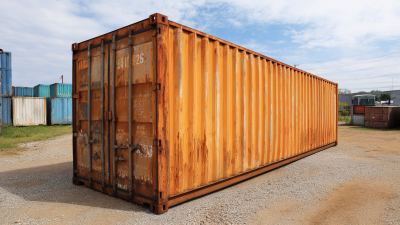

2025 Top Standard Shipping Container Size Guide for Shipping Industry

In the ever-evolving landscape of the shipping industry, understanding the nuances of logistics is paramount for optimizing operations and ensuring cost-efficiency. One of the critical elements in this realm is the "standard shipping container size", which plays a vital role in determining shipping costs, storage efficiency, and the overall effectiveness of supply chain management. According to a recent report from Deloitte, the global shipping container market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, illustrating the importance of adhering to standard measurements for maximizing cargo potential.

As shipping standards continue to evolve, industry stakeholders must remain informed about the various container sizes and their applications. The International Organization for Standardization (ISO) has established standardized dimensions that facilitate international trade, ensuring compatibility across different modes of transport. A comprehensive understanding of these dimensions not only aids logistic companies in improving their operational efficiency but also helps businesses in planning their inventory and shipping strategies more effectively.

Equip your logistics operations with the latest insights and best practices, allowing them to thrive in a competitive market by leveraging the advantages provided by utilizing the correct standard shipping container size.

Top Standard Shipping Container Sizes: An Industry Overview for 2025

The shipping container industry is on the brink of significant growth, with projections indicating that the global shipping container market size will expand from USD 10.98 billion in 2025 to approximately USD 15.01 billion by 2034. This growth represents an accelerated shift driven by the increasing demand for various container types, including dry containers, refrigerated containers, and tank containers, which are essential for transporting diverse goods across international markets.

In 2025, the overall shipping container market is anticipated to register a compound annual growth rate (CAGR) of 3.6%, reaching USD 11.6 billion by 2035. Such expansion is fueled by the ongoing recovery in global trade and the recent agreement between the United States and China to temporarily reduce tariffs, which is expected to stimulate container shipments between the two economies. As maritime shipping remains the backbone of world trade, the resilience of the container shipping sector will play a crucial role in meeting the evolving demands of a globalized economy.

Key Dimensions and Capacities of ISO Standard Containers

When it comes to shipping goods internationally, understanding the dimensions and capacities of

ISO standard containers is crucial for

efficient logistics management. The most commonly used shipping containers are the

20-foot and

40-foot variations, with the

standard 20ft container measuring

6.06 meters in length,

2.44 meters in width, and

2.59 meters in height. This allows for a

maximum payload of around

28,000 kg, making it ideal for heavy but

compact cargo. Conversely, the 40ft container doubles the capacity with a length of

12.19 meters, allowing for increased

shipping volume without requiring additional trips.

Tips: When planning shipments, it’s

imperative to consider not just the size but also the internal dimensions of the containers to

ensure that your products fit well. Make sure to account for any packaging materials that could

affect the total space required.

Additionally, specialty containers, such as refrigerated or open-top versions, serve specific

shipping needs. A refrigerated container (REEFER) maintains temperature-sensitive goods, while

an open-top container is advantageous for tall items that wouldn’t fit in a standard container.

Always confirm the specifications of the container type you choose to avoid potential delays in transit.

Tips: Always check the container’s

tare weight and payload limits before loading to maximize efficiency and avoid overloading penalties.

Impact of Container Sizes on Shipping Costs and Logistics Efficiency

The impact of container sizes on shipping costs and logistics efficiency is profound in the shipping industry. With the global trade market continually evolving, the choice of container size can significantly influence operational expenses. According to the International Maritime Organization (IMO), standardized container sizes, particularly the 20-foot and 40-foot containers, have dominated global shipping, accounting for over 90% of containerized cargo. This standardization not only facilitates easier stacking and transport but also optimizes space utilization on vessels, thereby reducing per-ton shipping costs.

Moreover, varying container sizes can affect logistics efficiency. A report from Drewry Maritime Research indicates that utilizing larger containers, such as 45-foot or even 53-foot units, can lead to a 10-20% reduction in shipping costs per unit due to economies of scale. However, companies must weigh these potential savings against the increased difficulty in handling and potential disruptions in narrow ports where larger containers may not fit. Consequently, understanding the implications of container sizes is essential for businesses aiming to enhance their logistics strategies while effectively managing shipping costs.

Trends in Shipping Container Sizes: Adapting to Global Trade Needs

The shipping industry is witnessing significant trends in container sizes to adapt to the evolving global trade landscape. As the global container ship market is projected to grow from $15.37 billion in 2025 to $21.40 billion by 2032, it’s clear that shipping companies are increasingly focused on optimizing their fleet to meet demand. Factors such as trade policies and fluctuating shipping volumes play a crucial role in shaping container sizes and types, with a noted impact on U.S. container rates due to weak demand.

Tips for adjusting to sizing trends include accurately assessing market needs before expanding capacity. It's essential to stay informed about changes in trade regulations that can affect container availability and rates. Additionally, consider investing in high-cube containers which provide more space and flexibility for various cargo types. Adopting a multi-container strategy can also mitigate risks associated with demand drops and help maintain competitive shipping rates across different trade routes.

Comparative Analysis: 20ft vs. 40ft Containers in Modern Shipping Practices

In the modern shipping industry, the choice between 20ft and 40ft containers is pivotal, influencing both logistical efficiency and cost management. According to the International Maritime Organization (IMO), 20ft containers account for approximately 60% of the global container fleet, making them the most commonly used. Their compact size is advantageous for smaller shipments, allowing for better maneuverability in ports and more flexible loading options. This is particularly beneficial for businesses that require frequent and diverse shipments, as smaller containers can reduce the need for large-scale warehousing.

On the other hand, 40ft containers have gained popularity due to their capacity to hold more cargo—approximately double that of their 20ft counterparts. Reports from the United Nations Conference on Trade and Development (UNCTAD) indicate that 40ft containers are increasingly preferred for bulk shipments to maximize freight efficiency. This choice significantly lowers the cost per unit transported, essential for companies looking to maintain competitive pricing in saturated markets. As sustainability becomes a pressing concern, using larger containers can also reduce carbon emissions per ton of cargo transported, aligning with the industry’s environmental goals. Thus, both container sizes play crucial roles in shaping logistical strategies, depending on specific shipping needs and operational constraints.

2025 Top Standard Shipping Container Size Guide for Shipping Industry - Comparative Analysis: 20ft vs. 40ft Containers in Modern Shipping Practices

| Specification | 20ft Container | 40ft Container |

|---|---|---|

| External Length | 20 ft (6.058 m) | 40 ft (12.192 m) |

| External Width | 8 ft (2.438 m) | 8 ft (2.438 m) |

| External Height | 8.5 ft (2.591 m) | 8.5 ft (2.591 m) |

| Internal Length | 19.4 ft (5.898 m) | 39.4 ft (12.032 m) |

| Internal Width | 7.7 ft (2.352 m) | 7.7 ft (2.352 m) |

| Internal Height | 7.9 ft (2.393 m) | 7.9 ft (2.393 m) |

| Maximum Gross Weight | 24,000 lbs (10,886 kg) | 48,000 lbs (21,772 kg) |

| Tare Weight | 4,800 lbs (2,177 kg) | 8,000 lbs (3,629 kg) |

| Max Load Weight | 19,200 lbs (8,709 kg) | 40,000 lbs (18,144 kg) |

| Common Uses | Small shipments, personal relocations | Large shipments, commercial freight |

Conclusion

The article "2025 Top Standard Shipping Container Size Guide for Shipping Industry" provides a comprehensive overview of the various standard shipping container sizes essential for modern logistics. It discusses key dimensions and capacities of ISO standard containers, emphasizing how these sizes influence shipping costs and overall efficiency in the industry.

Additionally, the article highlights trends in container sizes as they adapt to the evolving needs of global trade, including a comparative analysis of 20ft and 40ft containers. As shipping practices evolve, future innovations are also explored, shedding light on emerging container sizes and their potential market impact. Understanding standard shipping container size is crucial for businesses looking to optimize their shipping strategies and improve logistical operations.

Related Posts

-

Understanding the Dimensions of Standard Shipping Containers for Your Next Project

-

Unlocking Savings: The Ultimate Guide to Discount Shipping Containers for Your Next Project

-

Exploring the Versatility of 20 ft Cargo Containers: Innovative Uses for Storage and More

-

Maximizing Space: Innovative Uses for Your 20 ft Shipping Container You Haven't Considered

-

10 Best Uses for 20 ft Sea Containers in Your Business and Home

-

20 ft Storage Container Tips to Maximize Space and Efficiency for Your Needs