How to Choose the Right Storage and Shipping Containers for Your Needs

In the rapidly evolving landscape of logistics and supply chain management, choosing the right storage and shipping containers is more critical than ever. According to a report by the Container Owners Association, the global demand for shipping containers is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years. This trend reflects an increasing reliance on effective storage and shipping solutions, driven by the rise of e-commerce and global trade. As organizations strive to optimize their logistics processes, understanding the nuances of container selection becomes paramount.

Industry expert Dr. Emily Hart, a leading consultant in logistics management, emphasizes the importance of making informed choices: “The effectiveness of your supply chain can hinge on the containers you select. Properly suited storage and shipping containers not only protect your cargo but also enhance operational efficiency.” Her insights underline the necessity for businesses to consider factors such as container size, material, and purpose to ensure their logistics strategy aligns with their operational goals.

As the industry continues to innovate, with advancements in materials and container designs, it is imperative for businesses to stay abreast of these changes. This guide will delve into the fundamental aspects that influence the selection of storage and shipping containers, providing you with the knowledge needed to make decisions that bolster your operational effectiveness in an increasingly competitive market.

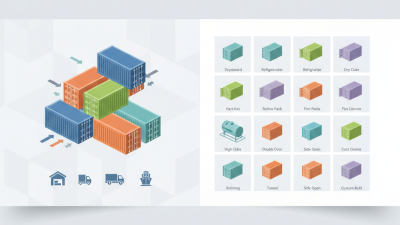

Understanding Different Types of Storage and Shipping Containers

When selecting the right storage and shipping containers, it's essential to understand the various types available, as each serves distinct purposes and requirements. One common type is the standard shipping container, typically made from steel, which is ideal for transporting large quantities of goods over long distances. These containers come in standardized sizes, allowing for easy stacking and storage in shipping yards or warehouses. Their durability makes them suitable for both domestic and international transport, providing a secure environment for various cargo types.

Another type to consider is the specialized container, designed for specific types of goods. For instance, refrigerated containers, or "reefers," are perfect for transporting perishable items that require temperature control. Alternatively, tank containers are utilized for liquids, ensuring safe and efficient transport of chemicals or food-grade liquids. Additionally, there are modular containers, which can be combined to create larger storage spaces or offices. Understanding these types and their specific features can help you make informed decisions tailored to your storage or shipping needs.

Assessing Material Choices: Plastic vs. Metal vs. Wood Containers

When selecting the right storage and shipping containers, understanding the differences between material choices—plastic, metal, and wood—is crucial to meeting your specific needs. Plastic containers are lightweight, resistant to many chemicals, and often water-resistant, making them ideal for industries that require cleanliness and easy transport. They come in a variety of shapes and sizes, providing flexibility for different storage needs. Additionally, their durability allows for repeated use without significant wear and tear, making plastic containers a cost-effective choice for long-term operations.

On the other hand, metal containers, particularly those made of steel or aluminum, offer unmatched strength and security. They are well-suited for shipping heavy and bulky items, as they can withstand considerable pressure and harsh environmental conditions. Metal containers can also be customized with features such as ventilation and insulation, catering to specific storage requirements. However, their weight and potential for rusting without a protective coating can be drawbacks in certain situations.

Lastly, wood containers provide a classic option that combines strength with a certain level of aesthetic appeal. They are often favored for their natural insulating properties, making them suitable for temperature-sensitive items. Wood is easily accessible and can be sourced sustainably, adding an eco-friendly angle to your choice. However, they are generally heavier than plastic counterparts and may require treatment to prevent degradation from moisture and pests. Each material serves distinct purposes, and careful consideration is essential to identify the best fit for your storage and shipping needs.

How to Choose the Right Storage and Shipping Containers for Your Needs

| Container Type | Material | Durability | Weight | Cost | Best Use Cases |

|---|---|---|---|---|---|

| Plastic Container | Plastic | Moderate | Lightweight | Low | Food storage, chemical containment |

| Metal Container | Metal | High | Heavy | Moderate to High | Heavy equipment, construction materials |

| Wooden Container | Wood | Moderate | Moderate | Moderate | Furniture transport, home moving |

| Corrugated Box | Cardboard | Low | Lightweight | Very Low | Shipping small items, retail packaging |

Evaluating Size Requirements Based on Industry Standards and Applications

When evaluating size requirements for storage and shipping containers, it’s essential to consider industry standards and applications specific to your needs. According to a report from the International Maritime Organization (IMO), the most commonly used shipping container sizes are 20-foot and 40-foot equivalents. These containers are designed to optimize space while adhering to global shipping regulations. The ability to stack these containers efficiently allows for better space utilization on cargo ships and at storage facilities. Understanding these dimensions can significantly impact shipping costs and warehouse management.

Moreover, industry reports indicate that the capacity of a standard 20-foot container is approximately 28,300 liters, while a 40-foot container holds around 57,600 liters. This capacity can influence inventory decisions across various sectors, from pharmaceuticals to food services, where temperature-controlled options are often required. In a recent survey by the Global Container Shipping Industry, 75% of businesses stated that container size directly affects their logistic planning, emphasizing the importance of accurately assessing storage needs before making a decision. Proper evaluation of size requirements can lead to enhanced efficiency, reduced costs, and improved operational workflows.

Cost Analysis: Budgeting for Container Purchase and Maintenance

When it comes to selecting the right storage and shipping containers, understanding the cost implications is crucial for effective budgeting. The initial purchase price of the containers is often just the tip of the iceberg. Various factors contribute to the overall cost, including the size, material, and any special requirements you may have for the containers. For instance, opting for environmentally friendly materials or custom modifications can significantly increase the upfront investment. It’s essential to conduct a thorough cost analysis to ensure that you’re considering not just the purchase but also the long-term expenses associated with shipping and maintenance.

Maintenance costs can also accumulate over time. Containers subjected to harsh weather conditions or frequent handling may require regular inspections and repairs, adding to your overall budget. It’s advisable to set aside a portion of your budget specifically for maintenance, which can include rust treatment, structural integrity assessments, and cleaning. Additionally, consider how the location of their storage impacts costs—renting space for containers in high-demand areas may lead to increased expenses. A comprehensive understanding of these budgetary considerations will help you make a well-informed decision, ensuring that your choice of storage and shipping containers aligns with your financial expectations and operational needs.

Regulatory Compliance: Ensuring Containers Meet Safety Standards

When selecting storage and shipping containers, one of the most critical considerations is regulatory compliance. It is essential to ensure that the containers meet safety standards established by relevant authorities, as non-compliance can lead to severe consequences. Different types of goods have varying requirements; for instance, containers used for hazardous materials must adhere to specific regulations that govern the materials' storage and transportation. Understanding and implementing the necessary compliance measures can prevent safety incidents and legal issues.

Additionally, proper documentation is crucial when evaluating container options. Certifications and inspection records should be thoroughly reviewed to ensure they align with industry safety standards. This not only guarantees that the containers are suitable for their intended purpose but also provides peace of mind for businesses regarding liability. By prioritizing regulatory compliance during the selection process, companies can protect their assets, safeguard employees, and maintain a robust reputation in the market.

Related Posts

-

What is the Best Option for Storage and Shipping Containers for Your Needs

-

10 Best Shipping Containers for Your Storage and Shipping Needs in 2023

-

20 ft Cargo Container: Best Uses, Costs, and Buying Tips for Beginners

-

20 ft Storage Container Tips to Maximize Space and Efficiency for Your Needs

-

2025 Top 5 Reasons Why 20 Ft Cargo Containers are Essential for Businesses and Shipping Industry Growth

-

How to Choose the Best Steel Shipping Containers for Your Needs