How to Choose the Right Shipping Containers for Your Needs?

When selecting the right shipping containers, clarity is key. Tom Barker, a shipping containers expert, states, “Choosing wisely can save you money and headaches.” Shipping containers come in various sizes and conditions. Understanding your needs can be overwhelming.

Consider the purpose of your shipping containers. Will they be used for storage or transport? The choice will greatly impact your budget and efficiency. Each container type offers different advantages and drawbacks. For example, a new container is more expensive but often comes with fewer issues.

A less-than-perfect choice can lead to unnecessary expenses. An improperly sized container may result in transporting goods multiple times. The decision requires thoughtful reflection on your unique situation. Doing thorough research will guide you to the best option for your needs.

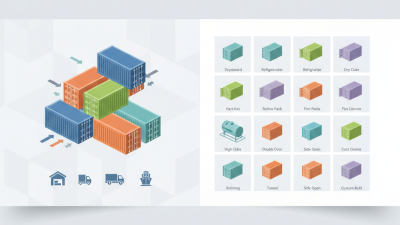

Understanding Different Types of Shipping Containers Available

Shipping containers come in various types. Each serves unique needs. Understanding these differences is crucial for effective logistics.

Standard containers are the most common. They come in sizes like 20ft and 40ft. According to the International Organization for Standardization (ISO), over 90% of global trade is conducted using these containers. They are perfect for general cargo. But not every shipment fits into these boxes.

There are specialized containers as well. Refrigerated containers, or "reefers", maintain specific temperatures for perishable goods. A report from the Council of Logistics Management suggests that the demand for reefers will grow by 4.5% annually. There are also open-top and flat-rack containers for oversized items. Each type has advantages and limitations. Knowing these options helps avoid costly mistakes. Choosing the wrong container can lead to damage or delays in shipping.

Assessing Your Shipping Requirements and Needs

When assessing your shipping requirements, consider your cargo type, volume, and destinations. Data suggests that over 70% of shippers face challenges related to improper container selection. This often leads to increased costs and delays.

Different materials are suitable for different goods. For example, a refrigerated container is essential for perishables. Distinct containers also offer varied load capacities. It's common for businesses to underestimate their shipment needs, leading to overcrowded spaces. Insufficient space can cause damage to your products.

Another factor is the duration of transit. Longer journeys may require sturdier containers. Research shows that 60% of damaged goods can be traced back to inadequate packaging. Keep an eye on trends, as transport regulations change frequently. It’s essential to stay updated. Quality inspection is often overlooked, yet crucial for ensuring the integrity of cargo. The challenges can seem daunting, but understanding your needs can streamline the process.

Factors to Consider When Choosing Shipping Containers

Choosing the right shipping containers is crucial for many businesses. Various factors influence this decision. Size is one of the most important aspects. Standard shipping containers come in sizes like 20 feet and 40 feet. According to industry reports, about 80% of the global shipping fleet consists of these two sizes.

Condition is another critical factor. New containers are essential for certain goods. However, used containers can be a cost-effective solution for others. Reports indicate that more than 30% of containers are sold as used. Always check for structural integrity, rust, and leaks. They could lead to losses in transit.

Finally, consider the cost. Prices can vary significantly based on market demand. In recent years, container prices have fluctuated due to global trade changes. The average price for a used 20-foot container was about $3,000 last year. Think about your long-term needs. Renting may be an option, but it often leads to higher overtime expenses. Reflect on your specific usage to make a more informed choice.

How to Choose the Right Shipping Containers for Your Needs?

| Factor | Description | Importance Level |

|---|---|---|

| Container Size | Determine the appropriate dimensions based on your cargo volume. | High |

| Container Type | Choose between dry storage, refrigerated, or specialized containers. | Medium |

| Condition | Decide between new, used, or refurbished containers. | High |

| Weight Limit | Ensure the container's weight capacity meets your cargo requirements. | High |

| Cost | Evaluate your budget constraints and pricing options. | Medium |

| Location | Consider the shipping route and destination access for the container. | Medium |

| Seller Reputation | Research the reliability and customer feedback of the supplier. | High |

Evaluating Container Condition and Quality for Durability

When selecting shipping containers, the condition and quality greatly affect durability. A container that looks fine externally may hide severe corrosion internally. Research by industry experts indicates that nearly 30% of used containers have structural issues. Proper inspection is essential to assess these hidden damages.

Containers should be free from rust and dents. Look for wear in corners and seals. A worn seal can lead to leaks, compromising cargo. Data suggests that 15% of containers are not watertight due to seal failure. Choosing a container with a solid floor is crucial; damaged flooring can weaken the overall structure.

Consider environmental factors as well. Containers in harsh climates often face more wear. Reports indicate that containers in humid areas deteriorate 20% faster. It's also vital to understand cargo requirements. Some cargo demands specific temperatures or humidity levels. Thus, a simple inspection might not suffice. Careful evaluation is necessary, as what seems perfect may require deeper reflection on its condition.

Cost Analysis: Budgeting for Your Shipping Container Options

When budgeting for shipping containers, cost analysis is essential. Prices vary based on size, condition, and location. For example, a new 40-foot container can range from $3,000 to $6,000, while a used container may cost between $1,500 and $3,000. Understanding these ranges helps in making informed decisions.

Maintenance is another crucial aspect of budgeting. Regular inspections and minor repairs can add up. Research indicates that maintenance can cost around 10-20% of the initial purchase price annually. It's prudent to set aside funds for unforeseen damages as well. Dents or rust could lead to higher expenses if not addressed early.

Consider transport costs too. Delivery fees vary widely based on distance and local regulations. According to industry reports, these costs can add an additional 15-25% to your budget. Planning for these aspects ensures you remain within financial limits. Ultimately, a comprehensive financial overview will guide your choice effectively.

Related Posts

-

10 Best Shipping Containers for Your Storage and Shipping Needs in 2023

-

Unlocking Savings: The Ultimate Guide to Discount Shipping Containers for Your Next Project

-

How to Buy Second Hand Shipping Containers for Your Needs and Budget

-

Exploring the Versatility of 40ft Containers in Modern Logistics Solutions

-

2025 Top 5 Reasons Why 20 Ft Cargo Containers are Essential for Businesses and Shipping Industry Growth

-

20 ft Storage Container Tips to Maximize Space and Efficiency for Your Needs